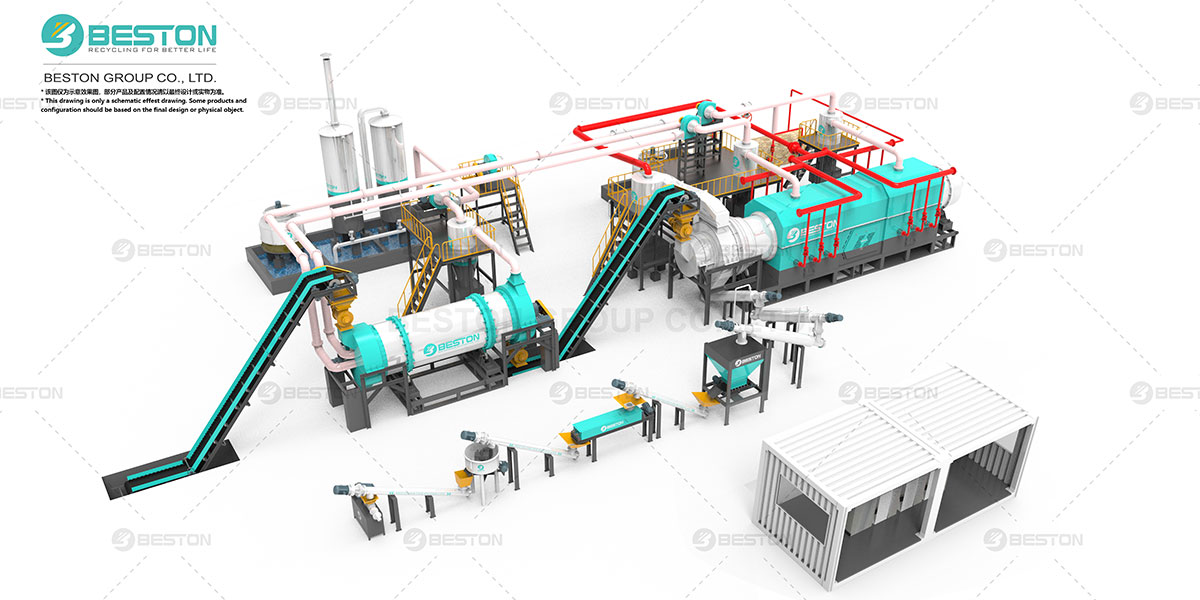

A charcoal-making machine is an ingenious contraption that can transform ordinary bio-waste into a top-quality charcoal product suitable for a wide range of applications. Charcoal and biochar have been an important part of our agricultural society since the early days of the agricultural revolution and this valuable commodity shows no sign of going obsolete.

Better still charcoal making machine allow the modern entrepreneur a new and profitable solution to the growing waste management crisis.

A suitable charcoal making machine can support the needs of a community of industry niche by transforming the locally produced waste materials into a top-quality product in high demand. In the following article, we will take a closer look at what the charcoal making machine can do and how you can choose the right option for your needs.

How to Transform Waste Materials into Charcoal

The modern charcoal making machine can be fed with all types of collected organic matter that will be transformed into a clean and efficient source of fuel. Some of the most common materials that can be used in a biochar machine include rice husks, scrap wood, sawdust, and many other bi-products of the agricultural or construction industries.

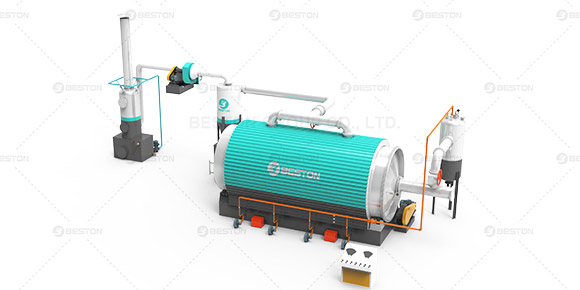

Through the chemical process of “pyrolysis”, these waste materials can be changed into something useful and applicable to modern needs. Here is how this is accomplished in the most advanced charcoal making machines on the planet.

Drying & Carbonization — the first step in the product removes all moisture from your bio-waste materials. This part of the process also improves the carbon content of the biomass thus increasing its energy content.

1. Recycling Combustible Waste Gas

One of the biggest problems with the pyrolysis process — “pyrolysis” being the chemical transformation that takes place when something is burned in a low oxygen environment. A considerable amount of waste gasses can be released during the process and this is no good for the environment. But this potential problem is just another opportunity with modern biochar production equipment. These gasses and fumes produced in the process come from valuable substances being vaporized within the machine. When collected, these gasses can be condensed into resins, wood vinegar, and syn-gas, which can be sold for market value.

2. Dealing with the Smoke

Another issue that is a common problem in the process of producing large quantities of top-quality charcoal is the vast quantity of dust and smoke that is produced in the process. Make sure the charcoal machine you choose for your operations has the proper components to control the amount of smoke and dust released into the air.

Choosing the Best Wood Charcoal Making Machine

If you are looking to improve your financial prospects with the production of top-quality charcoal products, you will need the right machine for your operations. Here are some more important considerations for your project:

1. No Residue and Reused Energy — some of the better charcoal making machines offer improved energy efficiency by using collected gasses as energy to be used in the carbonization process.

2. Adequately Priced — the most expensive option is not always the best. Take the time to consider the values you would like to see emphasized in your small charcoal making machine before you begin examining options. This way you will know exactly what type of components you will need in your climate and industry.

3. Top Quality

Finally, take the time to examine the reputation of your machine manufacturer. You will find that similar machines may have very different price tags. Make sure you investigate the reasons for price differences so that you can get the most profits for your investment.