The rubber-tyred gantry crane, commonly referred to as RTG crane, is a vital piece of equipment in the world of logistics and maritime operations. Known for their versatility, efficiency, and mobility, these cranes play a pivotal role in handling and moving containers and heavy loads at ports, container yards, and intermodal facilities. To understand the functionality and significance of RTG cranes, one must delve into their various parts and components that work in harmony to ensure smooth and effective cargo handling operations.

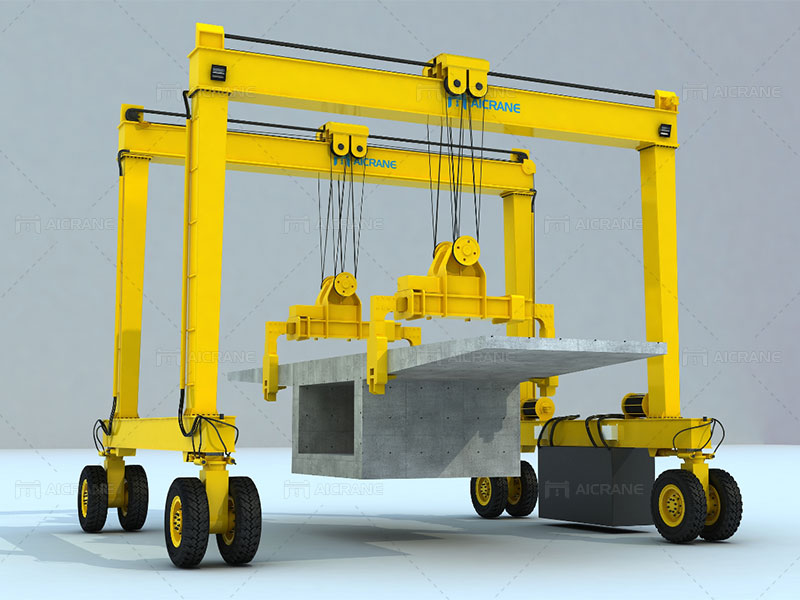

1. Gantry Structure:

The gantry structure is the core framework of the rubber tyre gantry crane. Comprising vertical legs and horizontal beams, the gantry provides the crane with stability and support. It is typically made of high-strength steel to withstand the heavy loads and harsh environmental conditions it encounters.

2. Rubber-Tyred Wheels:

One of the defining features of RTG cranes is the presence of rubber-tyred wheels. These specialized wheels are designed to run smoothly on paved surfaces, offering excellent maneuverability. The wheels are powered by electric motors, allowing the crane to move in any direction, including sideways (crabbing), which is particularly advantageous when handling containers in confined spaces.

3. Hoisting Mechanism:

The hoisting mechanism is responsible for lifting and lowering containers and other heavy loads. It consists of a hoist drum, wire ropes, and a spreader. The hoist drum is powered by an electric motor and is connected to the wire ropes that run through the crane’s boom. The spreader, which attaches to the wire ropes, securely holds onto containers during lifting and moving operations.

4. Spreader:

The spreader is a crucial component that connects the crane to the cargo. It comes in various configurations to handle different types of containers, including standard 20-foot, 40-foot, and even larger containers. The spreader’s design ensures a secure grip on the containers, minimizing the risk of accidents during lifting and transferring operations.

5. Boom or Outreach:

The boom, also known as the outreach, is the extended arm of the RTG crane. It houses the wire ropes and is capable of extending over the containers or cargo, allowing for efficient loading and unloading operations from ships and trucks.

6. Trolley and Crabbing Mechanism:

The trolley is the mechanism that moves along the boom, facilitating the horizontal movement of the spreader. Combined with the crabbing capability of the rubber-tyred wheels, this mechanism enables the gantry crane to precisely position containers during handling operations.

7. Power Supply System:

RTG cranes are typically electrically powered for environmental and operational efficiency. They can be connected to a power grid or equipped with onboard generators to provide the necessary electricity for the crane’s various operations, including wheel movement, hoisting, and other auxiliary systems.

8. Control Cabin:

The control cabin is where the crane operator sits and oversees all crane operations. Equipped with advanced control systems and displays, the cabin allows the operator to monitor loads, movements, and safety parameters. Modern control systems often include real-time data feedback, enhancing the operator’s ability to make informed decisions.

9. Safety Systems:

Safety is paramount in crane operations, especially when dealing with heavy loads and dynamic movements. RTG cranes are equipped with various safety features such as load sensing systems, anti-collision systems, and alarms. These systems help prevent accidents and ensure the well-being of both the operators and the cargo.

10. Electrical and Control Systems:

The electrical and control systems of RTG cranes are complex and sophisticated. These systems manage the operations of the crane, including motor control, synchronization of movements, and communication between different crane components. Advanced automation and remote monitoring capabilities are often integrated into these systems to optimize efficiency.

11. Maintenance Platforms and Ladders:

Maintaining RTG cranes is essential for their longevity and reliable performance. Maintenance platforms and ladders are strategically placed on the crane structure to provide access for routine inspections, repairs, and maintenance tasks.

12. Bumper Systems:

To prevent accidental collisions between the crane and other lifting equipment, bumper systems are installed at various points on the crane. These systems absorb the impact and help prevent damage to both the crane and nearby structures.

In conclusion, rubber-tyred gantry cranes are vital assets in modern container handling operations, offering flexibility, efficiency, and precision. Their complex design comprises a range of essential components that work together to facilitate smooth cargo movement. From the gantry structure to the wheels, hoisting mechanisms, spreader, and advanced control systems, each part plays a crucial role in the crane’s overall functionality. As technology continues to evolve, these cranes are likely to become even more sophisticated, enhancing the efficiency and safety of cargo handling operations across the globe.